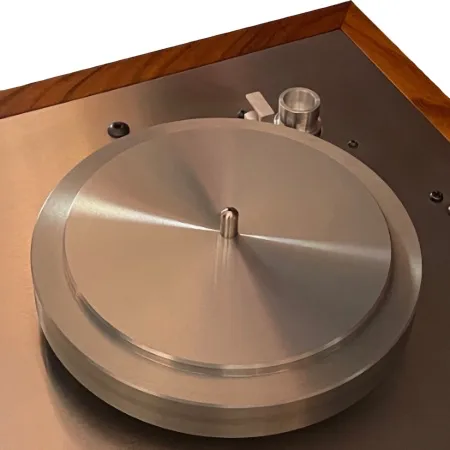

Platter

The platter of the LP12 is made from a metal alloy called Zamak (Zamak alloys are part of the zinc aluminium alloy family; they are distinguished from the other ZA alloys because of their constant 4% aluminium composition). It is one of the few parts on the LP12 that has remained virtually the same since 1973.

Some early platters had a thin felt strip glued on the underside of the rim to prevent scratches to the top-plate but that concept was abandoned early on. The factory-finished platters are carefully oxidised to produce a uniform grey layer and are then sealed with a clear lacquer. It is trendy to take older platters (with possible wear) and polish them to an almost chrome shine. Once the platter edge has been polished though, it will require continuous maintenance to retain the shine. [ See this article for one person's experience performing this job. ]

Sub-platter

This is one of the main parts of the LP12. It features the main spindle with the iconic one-piece conical tip that rides on top of the thrust plate in the main bearing. There are some aftermarket options available with exotic metal combinations.

Should you take off the sub-platter for whatever reason, always place it upside down, is shown in the photo below, to protect the tip of the spindle. If you have the original plastic cover that came with your turntable, then use it to close the spindle. Do not wipe it with paper towels or the like as this may introduce debris to the bearing once you reseat it.

As you can see from the photo above, my LP12 still has the older "pre-Cirkus" bearing with the recessed white liner. As long as it works and the subplatter spins freely when tested (with the belt off), leave it. There are not too many Cirkus kits available in South Africa, simply because of the cost of the newer Karousel bearing. You may order a pre-owned one online. Some claim the Cirkus bearing changes the musical character of the turntable. Better, or just different? I would not know.